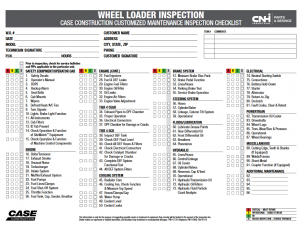

Maintaining your wheel loader is simple if you follow a wheel loader inspection checklist. It should cover all service points, including:

- Safety equipment & operator cab

- Engine

- Tier 4 CEGR

- Tier 4 SCR

- Cooling system

- Brake system

- Steering system

- Fluids & lubrication

- Hydraulics

- Electrical system

- Powertrain

- Miscellaneous additional maintenance

First of all, daily inspections alert the operator to potential breakdowns before they happen by revealing signs of wear and tear. The operator should check all fluids and do a visual check of tires, belts, and safety equipment. Pre- and post-use inspections provide an extra layer of safety that only costs a few moments each day.

Next, periodic maintenance by service personnel should be scheduled and performed without fail. Of course, it’s a good idea to keep records of all maintenance. Such records will prove to be invaluable, whether you’re evaluating the service life of your machines or trying to sell the equipment back to a dealer.

Another thing to consider is that operating your wheel loaders in harsh environments, or for extended periods, will require more frequent maintenance. If your operators are properly trained, they can help limit damage to your wheel loader, and will be more equipped to handle issues when maintenance items come up.

If you have any questions, or require service and repairs, don’t hesitate to call the experts at Eagle Power & Equipment at one of our numbers below.

- Montgomeryville, PA area – 215-699-5871

- Eagle, PA area – 610-458-7054

- New Castle, DE area – 302-652-3028